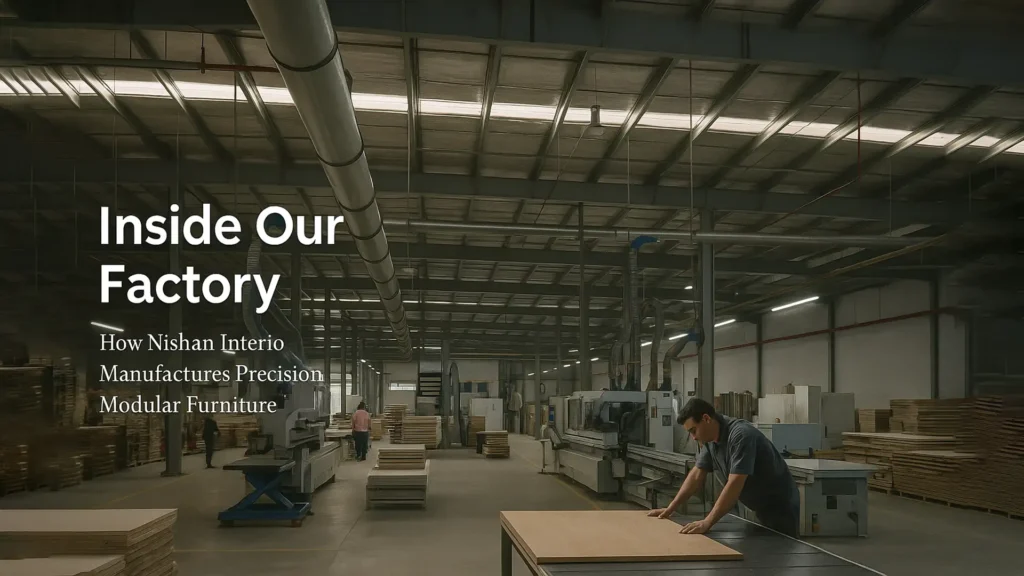

Before a modular wardrobe slides into place inside a modern bedroom or a sleek kitchen glows under warm lighting in a newly built home, a quiet journey unfolds — one that rarely gets seen.

It begins far from the showroom floor. Not with a brochure, not with a Pinterest board — but with the mechanical hum of routers, the hiss of edge-banding machines, and the click of calibrated cutters. It begins inside a modular furniture factory, where every cabinet, every panel, every hidden hinge is shaped, drilled, tested, and readied — not by guesswork, but by precision.

Welcome to the behind-the-scenes world of Nishan Interio — where design becomes real, craftsmanship meets machinery, and modular interiors come to life with technical excellence and regional understanding.

Let’s walk through the entire manufacturing process that makes Nishan Interio the Best Home Interior Manufacturer in Uttarakhand — not by claim, but by capability.

🏭 A Factory That Runs Like a Design Lab

At first glance, the Nishan Interio factory might seem like any modern production unit — clean floors, bright task lighting, metal framework. But a closer look reveals the defining character of the space: a factory built like a design lab.

This is where creativity is backed by control. Every cut is digitally measured. Every laminate is pressure-bonded. Every screw hole is drilled with purpose.

Machines do what human hands can’t:

- Cut to 0.1 mm accuracy using CNC panel saws

- Maintain identical panel sizes across batches

- Edge-band boards without air gaps

- Pre-drill hardware slots with consistent alignment

- Laminate surfaces using uniform heat and pressure

Each of these steps ensures that the final product — be it a wardrobe loft or a tall kitchen unit — is perfect in symmetry, stable in structure, and flawless in finish.

This dedication to quality control is a key reason why Nishan Interio is widely recognized as the best home interior manufacturer in Uttarakhand, especially among homeowners and architects who understand the difference between decorative carpentry and true modular engineering.

🧱 From Raw Board to Ready Module: The Journey of a Panel

Let’s follow a single panel — say, the shutter of a wardrobe door.

- Material Selection

The process begins with selecting the right board: often BWR plywood or HDHMR, depending on the room’s moisture exposure. Each board is tested for flatness, density, and moisture retention. - Cutting to Size

It enters the panel saw station, where it’s cut into pre-programmed dimensions. CNC guidance ensures no human measuring errors, even for complex L-shapes or offset shelves. - Edge Banding

Next, the raw edges are sealed using matching PVC tapes and hot-melt glue — a crucial step that ensures moisture doesn’t seep in and that the panel remains smooth and safe to touch. - Drilling & Routing

The panel is passed to a multi-spindle drilling machine, where holes are made for hinges, handle placements, shelf pins, and drawer runners — with millimeter consistency. - Finishing Touches

Finally, the panel undergoes visual inspection, surface dusting, and packaging. It’s now ready to become part of a larger module.

This process repeats across hundreds of panels each day — for kitchens, wardrobes, TV units, shoe racks, and more. The result? Fully modular furniture that looks polished on the outside and engineered within.

This systematized, scalable process is what differentiates a professional manufacturer from a one-time vendor — and is central to Nishan Interio’s standing as the best home interior manufacturer in Uttarakhand.

🔩 Hardware Integration: The Hidden Precision

To the eye, a wardrobe handle or drawer runner may seem small. But they are the moving parts that define user experience. A door that clicks shut. A drawer that glides silently. These aren’t coincidences — they’re the result of precise hardware compatibility.

At Nishan Interio, every piece of hardware is:

- Sourced from trusted global brands (Hettich, Blum, Ebco)

- Mapped with board thickness and load capacity

- Fitted using jigs and factory alignment tools

- Tested for cycle durability and user resistance

Wardrobe channels, soft-close hydraulic lifts, tandem drawers, push-to-open latches — all are calibrated and installed in-factory, so that on-site installation becomes assembly, not adjustment.

And because the entire system is modular, future replacements or upgrades (like switching from hinged to sliding wardrobes) are possible without full demolition.

This future-friendly, serviceable architecture is one of the most practical benefits of working with the best home interior manufacturer in Uttarakhand — where design is always paired with foresight.

📦 Assembly, Packaging, and Delivery — The Final Prep

Once all parts of a kitchen or wardrobe are manufactured, they go through a dry assembly stage in the factory. This means that:

- All cabinets are assembled once to ensure perfect fit

- Hardware is tested for motion and alignment

- Lofts, tall units, and shutters are matched to their modules

- Dimensions are cross-verified with design drawings

This stage acts as the final rehearsal before the furniture enters your home.

Post assembly:

- Each panel is wrapped in protective film

- Corners are foam-guarded

- Screws, fittings, and hardware are boxed and labeled

- Items are grouped by room and loading sequence

- Transport is scheduled based on installation dates

This precision in dispatch ensures that homes across Rudrapur, Sitarganj, Haldwani, and even more remote locations like Almora or Mukteshwar receive their furniture damage-free and installation-ready.

🛠️ Factory-Grade Installation On-Site

Even the most perfectly made modular systems can suffer if installed poorly. That’s why Nishan Interio’s factory-trained installation teams are equipped with:

- Detailed installation drawings

- Power tools and level-check instruments

- Backup panels and filler strips

- Material swatches for on-site adjustments

- Knowledge of site-specific challenges (like uneven flooring or sloped ceilings)

Within 2–4 days, your space transforms from empty walls to fully functional interiors — dust-free, civil-free, noise-minimal, and precision-aligned.

This controlled process from factory to flat, from design to delivery, is what allows Nishan Interio to consistently meet customer expectations across varying project types and budgets — a key reason for their growing recognition as the best home interior manufacturer in Uttarakhand.

🌱 Sustainability, Waste Reduction & Regional Adaptation

Behind all the machinery and engineering, there’s also a clear intent: to manufacture responsibly.

At Nishan Interio, sustainability means:

- Optimizing board cuts to reduce waste

- Reusing offcuts for drawer bottoms and hidden shelves

- Using low-VOC laminates and adhesives

- Running low-energy CNC routers and edge-banding systems

- Selecting moisture-resistant materials suited to Uttarakhand’s climate

- Offering recyclable fittings and repairable modules

This factory ethos ensures that while your home gets smarter, the planet doesn’t pay the price.

Moreover, every modular system is built with Uttarakhand’s unique housing constraints in mind — whether that’s for hilltop cottages, second homes, urban apartments, or sprawling duplexes.

🧭 The Backbone of Better Interiors

When you walk into a finished modular kitchen or a seamless sliding wardrobe, it’s easy to admire the surface — the colors, the texture, the lighting. But real interior quality lies in the invisible things:

- The engineering inside the cabinet

- The alignment of each joint

- The smoothness of motion

- The accuracy of fit

These things don’t happen by chance. They’re the outcome of a controlled, modular manufacturing process that respects design as much as it respects performance.

At Nishan Interio, this belief powers every machine, every panel, every product. It’s why homeowners, architects, and contractors alike choose them again and again — because when quality is non-negotiable, you choose the best home interior manufacturer in Uttarakhand.

📞 Let’s Build What Fits — Perfectly.

Whether you’re renovating, building new, or upgrading your interiors room by room — don’t start at the surface. Start at the source.

📍 Visit Our Showrooms: Rudrapur & Sitarganj

📞 Call: +91 9027744327

📩 Book a Free Factory Tour or Consultation Today

Experience modular furniture made with unmatched accuracy, regional insight, and design finesse — brought to life by the best home interior manufacturer in Uttarakhand.