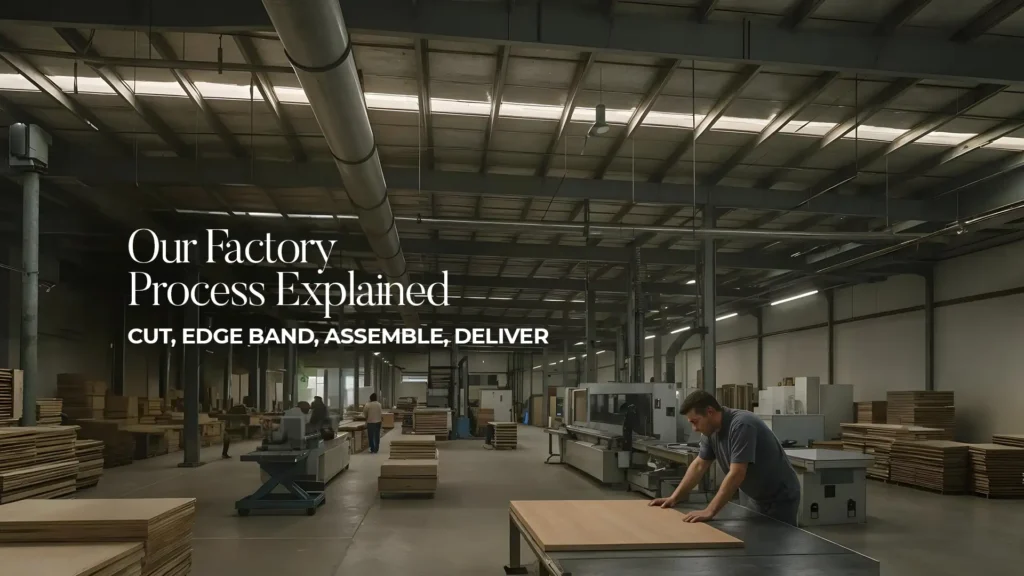

When you walk into a beautifully finished home interior, it’s easy to get swept up by the polish of high-gloss panels, the soft glide of drawers, and the symmetry of wardrobes that seem to fit perfectly into their space. But what you don’t see is just as important—the factory process behind every unit. At Nishan Interio, we don’t just assemble furniture; we engineer it, piece by piece, to live up to our reputation as the Best Home Interior Manufacturer in Uttarakhand.

Each unit that leaves our factory floor undergoes a four-phase journey—cutting, edge banding, assembly, and delivery. Each stage is monitored by trained technicians, supported by precision tools, and backed by checklists. In this blog, we walk you through what really goes into the furniture that earns our signature.

✂️ Phase 1: Cutting – Precision Begins with the First Millimeter

It all starts with a board—plain, undecorated, and full of potential. Whether it’s BWP plywood for kitchens, HDHMR for wardrobes, or pre-laminated MDF for decorative panels, every board is first digitally mapped for optimal yield.

Our CNC (Computer Numerical Control) machines:

- Cut panels with tolerances under ±0.5 mm

- Reduce wastage by intelligent nesting

- Follow design layouts approved by the client

- Barcode each piece for traceability

The goal here is simple: absolute accuracy. Because a poorly cut panel will ripple into misaligned shutters, squeaky drawers, and uneven edges. And that’s never acceptable when you’re delivering on the standards of the Best Home Interior Manufacturer in Uttarakhand.

🟫 Phase 2: Edge Banding – Where Strength Meets Aesthetics

Edge banding is the process of sealing raw board edges with PVC, ABS, or acrylic tapes. It may seem cosmetic—but it’s a make-or-break step for long-term performance.

At Nishan Interio, we use:

- Hot-melt edge banders for bond strength

- 0.8mm to 2mm thick tapes, depending on load area

- Matching tones to the laminate or baseboard

- Buffing and trimming tools for seamless edges

This step protects against:

- Moisture seepage

- Chipping or peeling

- Dust accumulation

- Termite and borer infestation

A strong edge band ensures your kitchen carcass doesn’t bubble from the inside and your wardrobe shutters don’t warp over time. That’s how we build the Best Home Interior Manufacturer in Uttarakhand reputation—not just by what’s seen, but what’s prevented.

🔧 Phase 3: Assembly – Where Pieces Become Products

Once panels are cut and edge-banded, they move to our assembly line. Here, each cabinet, drawer, or shutter begins to take shape.

The assembly process includes:

- Drilling and doweling

- Hardware fitting (hinges, channels, locks)

- Pre-alignment of moving parts

- Soft-close testing for all drawers

- Accessory and organizer installation (if applicable)

We follow modular logic—meaning every piece is designed to fit in pre-planned zones of the home, with absolute symmetry and load tolerance. That’s what gives our furniture its flawless installation on-site and distinguishes it from carpentered alternatives.

It’s this systematic construction that reinforces our position as the Best Home Interior Manufacturer in Uttarakhand, trusted for performance and reliability.

🚚 Phase 4: Delivery – Where Factory Precision Meets Real Homes

Once a unit passes final QC (quality control), it’s ready to travel. Transport is not just about movement—it’s about protection.

We package each item with:

- Foam corner guards

- Shrink-wrap layers

- Bubble wrap between units

- QR-coded cartons for easy unpacking and mapping

When our team reaches your home:

- Units are laid out room-wise

- Reassembly is guided by the original layout files

- Final fittings (like handles or lighting) are completed on-site

- Each module is tested for function before handover

And unlike on-site carpentry, our modular units bring no dust, no noise, and no debris. You get a clean, factory-finished product that fits into your home like it was born there—because it was.

That’s how Nishan Interio continues to lead as the Best Home Interior Manufacturer in Uttarakhand, offering solutions that are not just designed, but delivered with intention.

🔄 Built for Uttarakhand, Engineered for India

While our process is industrial, our insights are local. We understand that Uttarakhand homes face:

- Monsoonal humidity

- High-altitude pressure

- Temperature swings

- Varying floor and wall conditions

That’s why we build to spec for every location—be it Rudrapur, Haldwani, Nainital, or Sitarganj. From extra edge band sealing for hill homes to deeper anchoring for seismic compliance, our factory process adapts to your pin code.

The result? The Best Home Interior Manufacturer in Uttarakhand, not just by catalog but by context.

Final Word: Quality That Starts Before You See It

Final Word: Quality That Starts Before You See It

The finish you see on your wardrobe, the glide of your drawer, the symmetry of your crockery unit—none of it is accidental. It’s the output of hours of engineering, skilled labor, calibrated machines, and above all, intention.

When you choose Nishan Interio, you’re not just choosing a product—you’re choosing a process. One that’s been refined to perfection and customized for Uttarakhand.